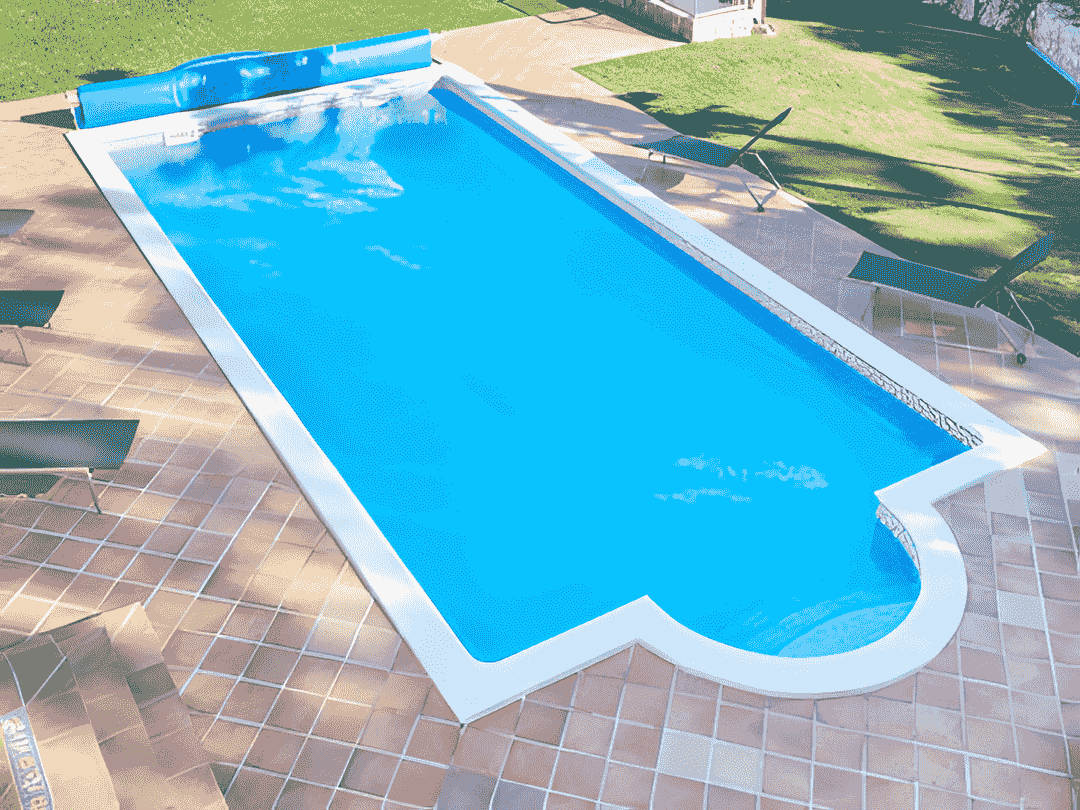

Waterproofing process of Swimming pool: A comprehensive Guide

Waterproofing a swimming pool is vital for giving it longevity and resistance over water leakage. Key objective of Waterproofing is to prevent the structure from leakage or other damages. This process includes utilisation of specialised chemicals, materials and techniques to establish a watertight barrier which is able to withstand the constant pressure of water. One of the leading service providers, Firstchoice Speciality chemical has key product and expertise that adds value to the client and makes a long-term relationship. In this blog, we will explore the steps involved in Waterproofing of swimming pools by using products and its availability in the market alongwith their actions for comprehensive understanding.

Steps of Waterproofing process of swimming pool

Step 1: Concrete repair and external rendering

Waterproofing of any structure starts with inspection of the present situation and concrete condition. It is recommended to begin waterproofing the swimming pool after assessing the pool's conditions and its concrete structure. Whether you are a homeowner or contractor, individuals must repair spalled concrete, cracks and other structural damages to give a stable base for waterproofing. For example- FCSC has CEMBOND SBR which is available in both B2B and B2C that acts as a high-performing bonding agent. Applying CEMBOND SBR helps to improve adhesion of the repair mortars in concrete surfaces. It makes it perfect for repairing floors, beams and precast slabs. FCSC as one of pioneers in this field suggest to use CEMBOND SBR for external rendering because it provides a waterproof, weatherproof and frost- resistance render to the surface from protecting the pool outer surface from any external substances. As everyone knows, swimming pools consist of various structures so applying CEMBOND SBR allows an additional layer particularly in basements, lift pits, inspection pits, water tower, liquid tanks and swimming pools. However, external rendering through CEMBOND SBR is able to make the masonry joints watertight and long-lasting that keep the swimming pool usable for many years.

Step 2: Waterproofing and tanking

After repairing and preparing the concrete structure, it is recommended to apply a waterproof coating to the pool's interior surfaces. In doing so, our CEMOCOAT AR can be ideal in this application which is available in the B2B segment. Our experts at FCSC designed CEMOCOAT AR particularly for Waterproofing and tanking that makes it appropriate for protecting swimming pools, basements and terraces from external threats. However, CEMOCOAT AR are waterproofing chemicals for swimming pools used as a bonding slurry coat and polymer modified flooring to expand its protection towards a significant extent. Apart from that, CEMOCOAT AR is also used for various applications starting from render key coat, render modification to patch repair mortar. At FCSC, CEMOCOAT AR adds value by preventing water from seeping through the concrete that helps to ratify that pool remains watertight. Some of our clients praise this product massively for working on large scale construction projects to achieve durability and reliability.

Step 3: Grouting and Joint filling

Grouting of concrete is followed by a waterproofing process which is essentially for addressing joint issues and minimising gaps within concrete structures. At FCSC, CEMGROUT GP is one of our key products available in B2B which remains ideal for high- strength and non- shrink grout. In Waterproofing of the pool, CEMGROUT GP is used for grout bearings, machine foundations and seamless column joints particularly in Precast construction in concrete. Key feature of CEMGROUT GP is flowability that ensures voids and gaps are filled appropriately, create seamless patterns and make sure it watertight. Apart from that, our experts checked the ideal water/ cement ratio and positive expansion through CEMGROUT GP which is a waterproofing admixture for concrete that is designed for Cementitious grouts especially in bed grouting, duct grouting and jointing.

Step 4: Anti- leakage coating

Coating should be perform after grouting in which our AQUAPROOF IW is a highly effective admixture that gives an additional protection layer to the pool surface and keeps it damage free. AQUAPROOF IW as a anti- leakage costing element able to waterproof the roof slabs and screeds, basements, sewerage works and external plastering. In giving coating, AQUAPROOF IW can be directly mixed into the concrete that is able to enhance its impermeability and also ensures the pool is leakage free. Apart from that, FCSC has the best primer for Waterproofing such as CEMOCOAT that protects the swimming pool from water- related issues and also brings longevity to it.

Step 5: Waterproofing PU injection Grouting

After performing anti- leakage pool coating, it is suggested addressing any cracks or porous concrete by using Waterproofing PU injection grouting. It is effective for Waterproofing because it involves injecting polyurethane based grout into cracks, which increases and seals the gals while preventing water from seeping through. Application of PU injection grouting is suitable

for addressing leakage in existing pools and also ensures the structure remains watertight without replacing any parts. Overall, CEMGROUT AD also can be used with PU injection grouting to increase concrete's effectiveness, preventing cracks and bringing durability in future.